Each veteran hydronic skilled is acquainted with the feeling of getting into a real “masterpiece” of a mechanical room. It’s a triumph of business geometry: inflexible copper strains working in good parallel, laser-straight runs of PEX being clipped to unistrut, and the gleaming repetition of 90-degree elbows. We contemplate this symmetry to be a badge of expertise. We take images of it. We put up it on social media. We decide our friends by the straightness of their strains.

However physics has one other perspective on it. Physics doesn’t understand that wall of proper angles to be artwork however sees it as a “parasitic load.”

For many years, the hydronics business has been battling a struggle towards friction, and the way in which it sometimes resolves that is with extra horsepower. We settle for that each one onerous turns in a piping system result in turbulence, stress drop (head loss), and noise. We’ve designed our methods in response to the constraints of producing—as a result of it’s simpler to extrude straight pipe and forged T-fittings—not in response to the legal guidelines of fluid dynamics. We make water go round corners it doesn’t wish to go round.

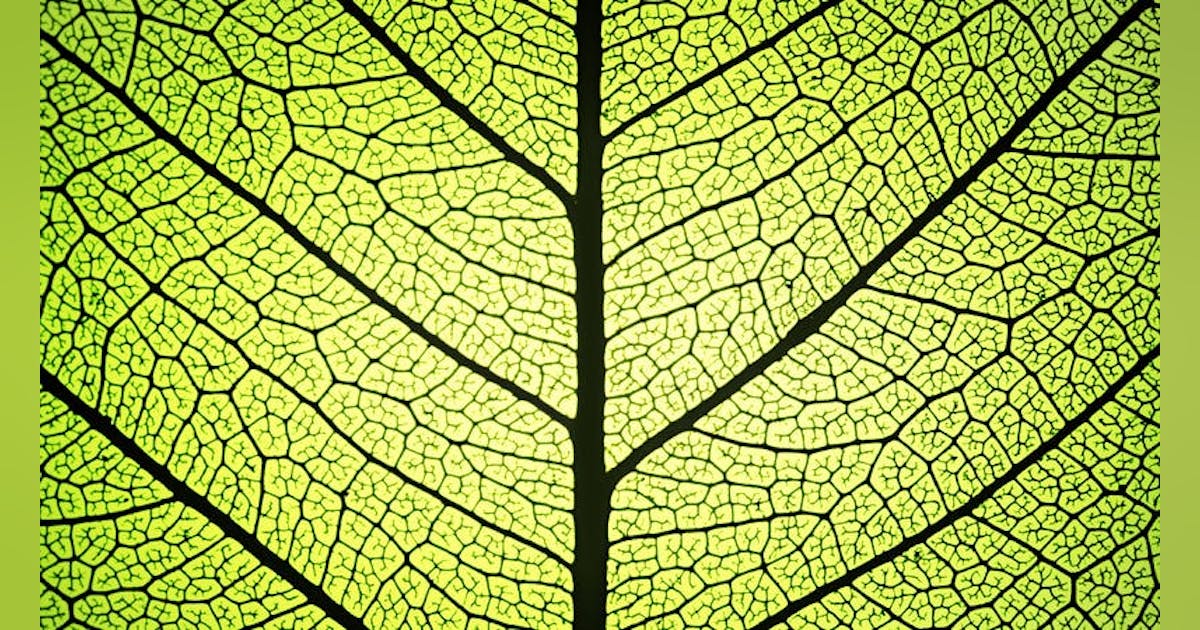

However nature has been transferring fluids for 400 million years (blood in veins, sap in timber, water in river deltas), and never as soon as has it employed a 90-degree flip.

We’ve hit the restrict of what’s potential when it comes to combustion effectivity; fashionable condensing boilers are pushing 98% AFUE. We’re following dwindling returns on the warmth supply. The subsequent main step in hydronic effectivity won’t be from a superior fireplace. It’s going to come from giving up “industrial geometry” in favor of the physics of life.

The Tyranny of the Proper Angle

With a purpose to perceive why the long run is curved, we should first perceive the violence of the correct angle. When water flowing at 4 ft per second hits the onerous 90-degree elbow, it does not simply flip; slightly, it crashes.

The liquid strikes away from the within wall, forming a low-pressure eddy, a “useless zone” of swirling turbulence. This limits the efficient diameter of the pipe, thereby growing the speed of the remaining water and leading to a rise of the friction head. For this reason we’re pressured to do difficult “equal size” calculations when sizing pumps. A single elbow isn’t simply an elbow; when it comes to friction, it’s truly 2 to five ft of straight pipe.

We’ve been coping with this friction with electrical energy for a century. We set up enormous pumps referred to as circulators to push the water across the obstacles that we put of their path. However what if there was no impediment?

The Science of Circulate: The Idea of Constructal Legislation

The roadmap for this transition is within the work of Professor Adrian Bejan at Duke College, who’s the daddy of Constructal Legislation.

Whereas the idea sounds educational, the precept is intuitive to anybody that has seen rain run down a windshield. Bejan’s regulation states, “For a finite-size system to persist in time (to dwell), it should evolve in such a means that it supplies simpler entry to the imposed currents that move via it.”

In commerce phrases, nature is all the time evolving in the direction of the trail of least resistance.

A river does not strike a tough 90-degree flip; it branches right into a delta with a view to decelerate and unfold water effectively throughout a plain. A human lung branches out into progressively smaller and smaller airways (bronchioles) with a view to present as a lot floor space as potential with out compromising on the stress. This isn’t unintentional. It’s the mathematical optimization of move.

Traditionally, mechanical contractors couldn’t pipe like this. You’ll be able to’t so simply forged a bronchial tube-like or root system-like bronze becoming. We had been caught with the T-fitting, the elbow, and the manifold bar as a result of they had been buildable, and never as a result of they had been environment friendly.

However that manufacturing barrier has lastly been damaged.

When Piping Mimics Biology

The appearance of Topology Optimization (AI-driven design software program) and Additive Manufacturing (3D printing) has introduced biomimetic design from the fields of theoretical physics to the provision home. We are able to now print manifolds, warmth exchangers, and impellers with a lowered resemblance to industrial equipment and extra like coral reefs.

The effectivity beneficial properties should not marginal, however exponential.

Researchers on the College of Illinois Grainger School of Engineering not too long ago used 3D printing to manufacture “power-dense” warmth exchangers utilizing these natural geometries. By merely letting the form of the construction emulate organic types, they maximized the move channels contained in the construction to reduce drag and maximize warmth switch.

The end result? They gained a 2000% improve in efficiency density when in comparison with conventional shell-and-tube designs.

Let that quantity sink in. This is not a 5% acquire in AFUE. It is a primary recasting of the query of the quantity of warmth we’re capable of transfer via a given quantity of house.

In line with in-depth critiques by the Nationwide Institutes of Well being (NIH) on constructions impressed by nature, the key lies within the upkeep of laminar move. In a typical hydronic loop, a circulator pump works towards the “minor losses” of every single becoming within the loop, making a move that’s turbulent and chaotic. In a biomimetic system, the water flows via gradual curves and tapering diameters. It maintains velocity with a fraction of the enter power, which helps to neutralize the friction, which is the bane of conventional piping.

The “Vascular Node”: Reshaping the Mechanical Room

What does this then imply for the bodily set up? It means that it’s the finish of the manifold as we all know it.

Presently, a radiant flooring manifold consists of a heavy copper or stainless-steel bar with welded tees. The water enters at excessive velocity and slams into the tip cap and is distributed into the loops in a turbulent method. It’s practical however crude.

Within the not-so-distant future, this shall be changed by a single, 3D-printed “vascular node.”

Think about a element that enters as a 1-inch pipe and splits into ten ½-inch loops, not by onerous tees, however via clean natural branches that appear like the arteries leaving the human coronary heart. The branching angles are designed by the pc algorithm particularly to equalize the stress throughout all of the zones with out having to steadiness valves.

The implications for system elements are enormous. Due to the extraordinarily lowered “head loss” (resistance) in these designs, the huge circulator pumps that we at present set up are overkill. We might be able to watch the transition to tiny, low-voltage sensible pumps that transfer water silently so there is not any turbulence noise to create the callbacks that everyone knows in high-end residential work.

The Set up Revolution

For the contractor, this isn’t merely high-minded physics—it’s a pragmatic labor answer.

The commerce is at present struggling an infinite scarcity of expert labor. We merely wouldn’t have sufficient apprentices studying the artwork of soldering good, plumb, near-boiler piping. A workaround is in biomimetic hydronics.

Take into account the period of time that it takes to assemble a posh major/secondary piping array: measuring, chopping, reaming, fluxing, and soldering 50+ joints. Now, think about that we will set up one pre-printed “vascular block” to attach the boiler with the distribution loops.

The result’s a drastic discount in labor hours—it may be 75% quicker set up instances and a 90% discount of leak factors. The much less of the chopping and soldering we do, the much less we leak.

Moreover, this shifts the method of design. We’re heading in the direction of Generative Design. As an alternative of a human drawing strains on a blueprint, a contractor will plug the warmth load and the room dimensions right into a software program platform. The software program will “develop” the piping format, optimizing the curves for the actual move charge required, and ship the file to a printer.

The Natural Plumber

We’ve spent the final century perfecting the machine. We’ve made the flame as environment friendly as it’s potential bodily. We’ve made the envelope hermetic by insulation. The one waste left that must be lowered is the friction within the pipe.

The adoption of Constructal Legislation means a maturity within the commerce. It’s the realization that we do not have to overcome water; we have to facilitate it.

The hydronic skilled of the long run won’t look a lot like a pipefitter however extra like a heart specialist. We would be the custodians of a dwelling, circulating system, putting in “vascular” elements that may respect, for the primary time, the legal guidelines of physics. We are going to alternate our proper angles for curves, our turbulence for silence, and our brute drive for move.

The 90-degree elbow had an honest run. It constructed the trendy world. But when we wish to develop the environment friendly world of tomorrow, it is time to float.

Trending Merchandise

CRAFTSMAN Pliers, 8 & 10″, 2Piece Groove Joint Set (CMHT82547)

TT TRSMIMA Safety Harness Fall Protection Upgrade 4 Quick Buckles Construction Full Body Harness 6 Adjustment D-ring

BIC Wite-Out Brand EZ Correct Correction Tape, 19.8 Feet, 4-Count Pack of White Correction Tape, Fast, Clean and Easy to Use Tear-Resistant Tape Office or School Supplies

![KwikSafety – Charlotte, NC – TSUNAMI KIT [Premium BRAIDED ROPE] Vertical Lifeline, 1-D Ring Safety Harness, Lightweight Tool Lanyard, Roof Anchor, 20L Dry Bag ANSI OSHA Fall Protection System / 50 FT.](https://m.media-amazon.com/images/I/51inmgg4jlL._SS300_.jpg)