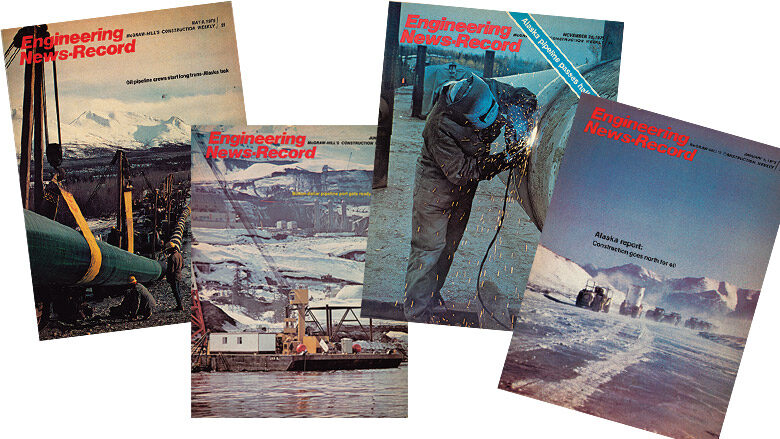

Transferring sizzling oil throughout Arctic terrain was an unprecedented problem following the invention of America’s largest oil subject in 1969 in Prudhoe Bay, Alaska. The primary hurdle the Trans-Alaska Pipeline needed to clear was environmental approval. The Nationwide Environmental Coverage Act was handed in 1969, the identical 12 months Alyeska Pipeline Service Co., a consortium of seven oil firms, introduced plans to construct the pipeline. NEPA required the Inside Dept. to supply an environmental impression assertion for the undertaking, which ran to 12,000 pages. Public hearings and court docket challenges performed out over 4 years. In late 1973, following the OPEC oil embargo, Congress overrode additional delays and cleared the pipeline from any extra NEPA-related court docket challenges.

The pipeline’s 796-mile route south from Prudhoe Bay crosses three mountain ranges, 20 main rivers and 300 streams earlier than reaching the ice-free port of Valdez. The best level, at 4,800 ft, was Dietrich Go within the Brooks Vary. Because the first-ever oil pipeline within the Arctic it posed severe design challenges. Seismic and floor circumstances weren’t preferrred. Some 420 miles of the route was over permafrost. The pipeline couldn’t be buried in these areas as the warmth of the oil would soften the permafrost, turning it right into a slushy mass with no bearing capability. The aboveground line rests on 36,000 metal bents and runs in a zigzag sample, permitting as much as 20 ft of horizontal and three ft of vertical pipe motion so it might endure earthquakes. Each 700 ft to 1,800 ft the pipes are clamped firmly to anchor assemblies to stop horizontal motion. Between the anchors the pipes are mounted in sliding shoe assemblies.

Alyeska selected Bechtel as building supervisor for the pipeline and haul highway, and Fluor as CM for the 12 pumping stations and a tanker terminal at Valdez. 5 contractors have been every awarded segments of the pipeline itself, which had been designed by Michael Baker Worldwide. Bechtel stationed 500 workers in Fairbanks. Early on, Alyeska admitted to start-up delays, some resulting from a lag in supply of drill rigs and drill bits, in addition to a sluggish begin on the Valdez oil tanks. A scarcity of mechanics and welders and a excessive turnover amongst laborers introduced additional difficulties. A 1975 ENR article said: “Many contractors proceed responsible building issues on the connection between Alyeska and Bechtel.” Alyeska ended Bechtel’s position as CM, and issued a brand new contract that designated the agency as “building/technical companies supervisor.”

The 84,000 bent piles needed to be pushed under the permafrost thaw space to supply sufficient bearing—anyplace from 22 ft to 50 ft deep. Regardless of hundreds of take a look at borings and soil samples, geotechnical surprises meant drilling gear was typically mismatched to soil circumstances, inflicting costly delays. For the reason that 48-in.-dia pipe was mounted solely 2 ft above grade, it posed a barrier to native wildlife. There are 554 areas with greater clearances to function animal crossings.

Preliminary building in 1974 noticed completion of a two-lane gravel haul highway working 350 miles from the Yukon River to the North Slope. The 28-ft-wide highway embankment was 5 ft thick to guard permafrost. Crews additionally constructed gravel work pads for the 5,000 items of apparatus and 29 work camps, every with a 5,000-ft gravel airstrip. By December 1974, there have been 3,000 employees engaged in drilling holes for piles, ending concrete footings for the Yukon River Bridge and blasting rock at Valdez to gouge an oil tank platform out of a mountain.

As a situation for acquiring a allow to construct a pipeline that traversed federal land for over two-thirds of its route, Alyeska agreed to an intensive federal and state surveillance effort to make sure environmental safeguards have been met. The Inside Dept. and state monitoring groups totaled 95 staffers, who had the suitable to cease work if obligatory, and did so a number of instances.

Hiring ramped up within the spring of 1975 and the workforce peaked at 21,600 that September, dropping by greater than half the next winter, with the cycle repeating in 1976.

Staff have been educated in Arctic survival by two former U.S. Military sergeant majors with Arctic expertise. Some factors talked about in a 1975 ENR article embody: “Heat water or urine can free naked palms which have rapidly frozen to instruments or different metallic … shelters will be dug in snow if employees are trapped outdoor … anybody who leaves camp should journey with a minimum of one different particular person.” Anybody touring by automobile needed to carry a sleeping bag in case of being stranded. Recognizing that lengthy working hours, chilly winters and restricted recreation might foster alcoholism among the many workforce, a union-contractor initiative inspired supervisors to intervene and steer candidates into 12-step restoration packages fairly than fireplace them.

One of many first sections of pipe positioned was a 1,900-ft part throughout the Tonsina River and its adjoining flood plain. 13 sideboom tractors walked the vinyl-wrapped pipe out on a 40-ft-wide gravel work pad and positioned it in a water-filled trench as much as 17 ft deep. The 300 ft of pipe beneath the energetic river channel had a 9-in.-thick protecting concrete coating. 9-ton concrete saddle weights pinned the pipe in place to counteract buoyancy till the road was crammed with oil.

Probably the most troublesome pipelaying was at Thompson Go within the Chugach Mountains, which had a slope of 47 °, the steepest on the route. Contractor Morrison-Knudsen had to make use of a kiloton of explosives to chop a 3,700-ft-long trench up the slope. A winch-driven cableway system carried spoil down and pipe sections and tools up. Personalized 92-ton tracked autos have been used to pump fine-grained backfill materials by way of 10-in.-dia hoses.

Union strife kicked up in 1975, regardless of a no-strike provision within the contract. A quick walkout of 4,200 employees over Teamsters’ grievances was ended by a court docket injunction. Later, nearly half of the two,000 welders walked off the job for 2 days after they have been denied the two-week relaxation and rest interval assured by their contract.

An orthotropic metal field girder bridge throughout the Yukon River was accomplished 4 months delayed in October 1975. The two,280-ft-long construction enabled heavy truck site visitors to entry the northern stretch of the undertaking. It additionally carried the pipe on an exterior, cantilevered metal framework. The pipeline crossed the Tanana River on a pipeline-only bridge with two 170-ft-high towers 1,200 ft aside— Alaska’s longest suspension span.

The terminal in Valdez alone price $1 billion to construct and featured 4 tanker berths and 18 oil storage tanks. Staff excavated 14 million cu yd of overburden to achieve bedrock. Every tank rested on an asphalt-sand-gravel cushion inside a concrete ring wall base. Welders assembled the 62-ft-high, 250-ft-dia metal constructions, every holding 510,000 barrels.

Alyeska put in Frank P. Moolin Jr. because the undertaking’s building supervisor in June 1975, following Bechtel’s demotion. Moolin decentralized authority, giving subject managers duty for making extra choices on their very own. He demanded detailed productiveness experiences. When work stopped for any motive, Moolin decreed that crews needed to be despatched again to camp the place they’d not be paid. He began a sweepstakes competitors among the many 5 contractors, charting their progress in opposition to their targets. All this strain helped put the undertaking again on monitor.

High quality management issues plagued the undertaking from mid-1975 by way of the end line. Alyeska found that 8% of the handbook welds in a 150-mile part of pipe had defects or deficiencies, and that quite a few X-rays of welds have been falsified. It set to work rechecking every of the three,748 welds in that part, nearly two thirds of which was buried, and fired the X-ray companies contractor on that part. The Inside Dept. and the U.S. Dept. of Transportation’s Pipeline Security Board ordered an impartial investigation of the weld X-rays and restore information for 30,800 welds finished in 1975. A whistleblower worker of the X-ray contractor testified earlier than Congress that he was pressured to falsify X-rays. President Gerald Ford despatched a federal fact-finding staff to Alaska in 1976 to look into the mess. By October 1976, Alyeska had repaired all 263 substandard welds, and X-rayed them once more, at a price of roughly $2,000 per weld.

As the biggest peacetime undertaking in U.S. historical past, the Trans-Alaska Pipeline had an outsized impression on Alaska. Fairbanks’ inhabitants doubled in measurement within the first 12 months to 60,000 from 30,000. Thirty two employees died in the course of the course of the undertaking.

Shortly after the final weld was made in June 1977, 27 months after the primary weld, oil started flowing southward from Prudhoe Bay at about 1 mph, reaching Valdez a month later. The oil entered the pipe at 140° F, and with friction offsetting cooling, maintains its temperature even in winter.

The ultimate price was $10 billion, closely impacted by excessive inflation and a roughly $1 billion overrun. The undertaking met its deadline, nevertheless, and ENR cited Moolin as 1977’s ENR Man of the Yr (now often called the Award of Excellence).

Trending Merchandise

CRAFTSMAN Pliers, 8 & 10″, 2Piece Groove Joint Set (CMHT82547)

TT TRSMIMA Safety Harness Fall Protection Upgrade 4 Quick Buckles Construction Full Body Harness 6 Adjustment D-ring

BIC Wite-Out Brand EZ Correct Correction Tape, 19.8 Feet, 4-Count Pack of White Correction Tape, Fast, Clean and Easy to Use Tear-Resistant Tape Office or School Supplies

![KwikSafety – Charlotte, NC – TSUNAMI KIT [Premium BRAIDED ROPE] Vertical Lifeline, 1-D Ring Safety Harness, Lightweight Tool Lanyard, Roof Anchor, 20L Dry Bag ANSI OSHA Fall Protection System / 50 FT.](https://m.media-amazon.com/images/I/51inmgg4jlL._SS300_.jpg)