The development trade has invested closely in digital instruments for greater than a decade, but stroll any job website and the identical issues persist. We’ve spent billions on BIM, digital twins, and visualization software program, however nonetheless face rework, poor set up high quality, and crews checking measurements by hand. Go searching and also you’ll discover tape measures, chalk strains, and conflicting benchmarks throughout the job website. It’s a reminder that our digital funding nonetheless stops on the trailer door.

The issue is easy and costly. We digitize the design however not the work. We construct detailed fashions, however the way in which we construct hasn’t progressed on the identical tempo. Till building digitizes its bodily workflows, instruments, and verification, digital twins will preserve falling in need of their promise.

A Damaged Thread: Design vs. Manufacturing

Mike Tyson as soon as stated, “Everybody has a plan till you get punched within the face.” In building, the mannequin is the plan, and the job website is the punch.

You pour concrete and the column strains are barely off. You begin hanging pipe and conflict with the present construction. Crews observe the plan however make discipline changes to accommodate what was constructed earlier than them. We’ve digital intent, however our discipline execution stays analog. The digital twin, which ought to replicate a dwelling course of, turns right into a static file that loses worth as quickly as actual work begins.

This disconnect prices actual cash. On one façade undertaking I labored on, two subcontractors shared accountability for adjoining panel sections put in in an alternating sequence. Each used completely different structure groups and barely completely different assumptions. One crew adjusted its spacing within the discipline to accommodate slab shifts, whereas the opposite adopted the structure drawings precisely. Each meant effectively, however these small changes turned main errors. As soon as their work was in contrast, the deviations exceeded what might be corrected within the discipline. 1 / 4-inch allowable tolerance turned inches of mismatch throughout the ground line.

This additionally raises a bigger query: what occurs when that very same façade is adjusted for slab circumstances, however inside partitions have already begun? If wall-to-mullion connections have tighter tolerances than the concrete, the change creates rework. If each commerce have been tied to the identical reside mannequin that up to date as-built circumstances in actual time, these issues would by no means attain set up.

We Are Digitizing Paper, Not Processes

These usually are not remoted errors–they present how disconnected digital coordination is from discipline execution. Knowledge movement stops on the website. With out structured suggestions, we depend on interpretation and reminiscence. Even the very best digital twin can not repair what it can not see.

As Hamzah Shanbari stated, the trade retains “digitizing paper, not course of.” Changing blueprints with PDFs will not be a change; it’s a translation. The software program modified, however the work didn’t.

From Tasks to Manufacturing System

The true impediment will not be expertise–it’s how we take into consideration tasks. Development treats each job as a one-off, whereas industries like manufacturing or power deal with theirs as manufacturing programs. Todd Zabelle wrote, “Till we acknowledge tasks as manufacturing programs and use operations science to drive undertaking outcomes, we’re doomed to failure.” With out visibility into manufacturing, there isn’t any suggestions loop, no correction, and no actual enchancment.”

Manufacturing is aware of the price of each delay as a result of it measures efficiency as a single steady system. Development calls itself too complicated for that, however the fact is extra simple—manufacturing manages its course of; building manages paperwork.

To handle building as a measurable course of, we want verifiable, structured information getting back from the sphere. Proper now, that suggestions is determined by individuals filling out day by day stories, checklists, or picture logs by hand. Some apps make this simpler, however the info remains to be subjective—it’s solely as dependable because the individual getting into it. With out goal information seize, there isn’t any dependable suggestions loop.

In manufacturing, sensors and machine logs feed information straight to regulate programs, giving managers a reside view of throughput, high quality, and downtime. Some processes nonetheless contain human high quality overview, however they’re a part of a structured system. Development has no such mechanism. Every contractor acts as an remoted station within the course of, largely resulting from danger mitigation issues. Contract language encourages separation and self-protection. There are few shared requirements for verification, so suggestions stays fragmented.

Think about if every workstation on a producing line have been an unbiased firm, every with its personal information, instruments, and danger profile. That’s how building operates immediately. The system works, however solely as a result of it should. The true alternative lies in constructing that very same construction by means of shared information, not management.

Market Pressures Demanding Change

Two forces are making this modification unavoidable. The primary is labor. For many years, skilled tradespeople made quiet discipline fixes when drawings conflicted or circumstances modified. That information base is disappearing as veterans retire. Youthful staff perceive the software program however lack the expertise to catch small errors earlier than they develop. With out data-driven verification, these errors now journey additional and value extra to repair.

The second is precision. The expansion of hypercritical infrastructure tasks—information facilities, battery services, and clear rooms—is driving house owners to demand greater ranges of element. Many now require LOD500 deliverables as commonplace. However gathering, processing, and organizing that a lot verified as-built info can price practically as a lot as constructing the undertaking itself. LOD500 offers the framework for true digital twins, however the price and overhead make it impractical for widespread use.

Bridging the Hole Between Knowledge and Work

3D scanners and robotic complete stations are a very good place to begin, however they’ve limits. Full-site scans can price tens to lots of of hundreds of {dollars} per undertaking and nonetheless require handbook setup and interpretation. Level clouds usually return unstructured and difficult-to-verify information. Floor-penetrating radar faces the identical drawback–it detects utilities and voids, however the information is delivered as flat anomaly maps as an alternative of geometric fashions.

Most companies keep away from interpretation due to legal responsibility dangers. Even when the information is collected, it arrives incomplete. Occlusions, restricted protection, and time gaps between scans go away important areas undocumented. It’s like a foul supervisor checking in often to ask, “Is every thing okay right here?” whereas lacking the hundreds of modifications in between.

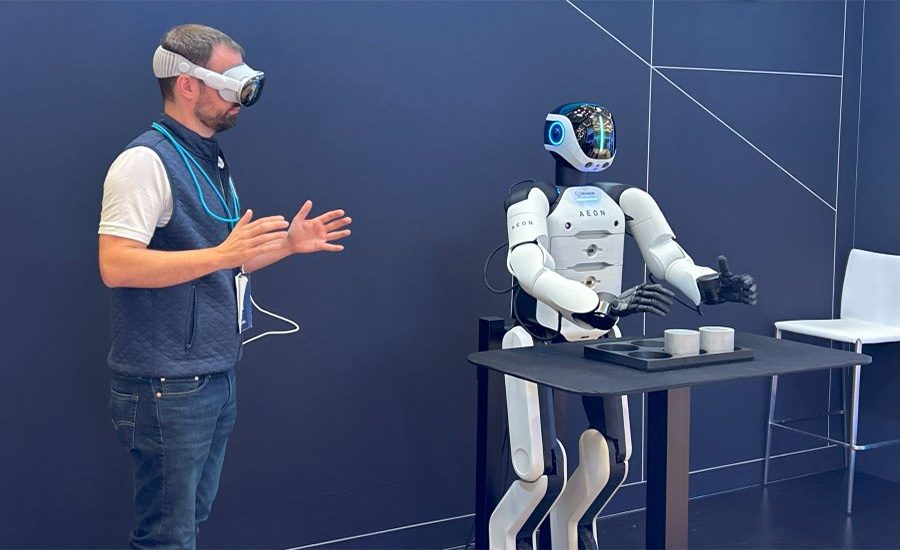

Automation modifications that by shifting information assortment from periodic to steady. Robots geared up with LiDAR, imaginative and prescient programs, and localization sensors accumulate information as they carry out their work. Every gap drilled, bracket positioned, or inspection accomplished provides on to the shared as-built mannequin. As an alternative of working round occlusions, the information is captured as these occlusions are being put in. The construction paperwork itself as it’s enclosed.

As a result of the information is generated because the work occurs, it contains geometry, context, and timing. This eliminates pauses, handbook registration, and the heavy post-processing required by conventional scanning. Documentation turns into a byproduct of the work itself. Robotic information assortment creates a steady digital heartbeat for the undertaking, much like a producing line, the place deviations are caught early and accuracy improves over time.

With automated verification, house owners can obtain LOD500 accuracy with out the price and documentation burden that beforehand made it unrealistic. Robots, sensors, and related instruments lastly shut the suggestions loop that digital twins have at all times promised.

The Path Ahead

The hole between mannequin and actuality is not going to shut by means of extra software program. It would shut by means of verified, steady suggestions from the sphere. Automation offers that connection, permitting each a part of the undertaking to measure itself in actual time and produce information that’s accountable and actionable. As an alternative of constructing a brand new digital twin at undertaking completion, the dual builds itself because the job progresses.

Automation is not going to remove the necessity for expert staff; it’s going to elevate them by giving them data-backed decision-making energy in actual time. Automation replaces assumption with proof, turns verification into collaboration, and transforms building’s static fashions into dwelling programs.

The query will not be whether or not building can digitize additional. It’s whether or not we are able to afford to not.

Conley Oster is co‑founder and COO of Increase Robotics. With a background in structural engineering and in depth expertise in crane and rigging operations on complicated building tasks, he now leverages his discipline experience to advance sensible robotic automation within the trade.

Trending Merchandise

CRAFTSMAN Pliers, 8 & 10″, 2Piece Groove Joint Set (CMHT82547)

TT TRSMIMA Safety Harness Fall Protection Upgrade 4 Quick Buckles Construction Full Body Harness 6 Adjustment D-ring

BIC Wite-Out Brand EZ Correct Correction Tape, 19.8 Feet, 4-Count Pack of White Correction Tape, Fast, Clean and Easy to Use Tear-Resistant Tape Office or School Supplies

![KwikSafety – Charlotte, NC – TSUNAMI KIT [Premium BRAIDED ROPE] Vertical Lifeline, 1-D Ring Safety Harness, Lightweight Tool Lanyard, Roof Anchor, 20L Dry Bag ANSI OSHA Fall Protection System / 50 FT.](https://m.media-amazon.com/images/I/51inmgg4jlL._SS300_.jpg)