Based on Autodesk and FMI, nearly 52% of all rework in development stems from inadequate undertaking knowledge and poor communication. As schedules tighten and margins face growing stress, contractors are trying to find higher methods to regulate their operations.

Fabrication-ready design gives an answer by enabling mechanical contractors to chop materials waste, pace installations and liberate their workforce to tackle extra initiatives. This strategy includes planning piping techniques within the workplace utilizing standardized elements, constant measurements and shop-friendly meeting sequences that translate immediately into environment friendly fabrication workflows. Though most of right now’s contractors have BIM instruments that make fabrication attainable, many have not totally tailored their design processes to leverage these capabilities. The next 5 practices bridge the hole between engineering specs and day-to-day fabrication store operations.

Finest Follow #1: Standardize Pipe Lengths and Spool Sizes

Step one towards fabrication effectivity is rounding measurements to determine customary sizes that cut back meeting variation within the store. Whereas most mechanical drawings specify pipe to the closest 1/sixteenth of an inch, this stage of precision creates pointless complexity. A ten-foot-3 9/16-inch spool and a 10-foot-3 1/2-inch spool require separate processing. Spherical each to 10 ft within the design and the fabrication course of creates half as many distinctive elements. BIM add-ins comparable to Victaulic Tools for Revit® (VTFR) might help automate this course of by standardizing lengths and suggesting applicable fittings throughout the modeling part.

Past simplifying particular person cuts, organizing spool fabrication schedules by measurement permits store groups to work with one measurement at a time. When slicing three-inch pipe all morning, employees arrange the slicing station as soon as and run by way of 50 items with out interruption. Switching to six-inch pipe means reconfiguring the station, a changeover that takes 30 to 60 minutes. Batching by measurement eliminates these interruptions.

The advantages lengthen past the store flooring as properly. Commonplace-length spools stack effectively in supply vehicles, maximizing area and decreasing transportation prices.

Finest Follow #2: Create Repeatable Connection Particulars

Transferring past particular person pipe lengths, contractors ought to develop standardized approaches for widespread connections like pump hookups, gear installations and valve assemblies. A typical pump hookup consists of isolation valves on each side, a verify valve, stress gauge, versatile connector, drain valve and a number of helps. Creating every connection from scratch wastes design time and complicates fabrication.

Remodel these widespread connection varieties into documented “merchandise” that may be replicated throughout a number of initiatives. Specify the precise sequence—for instance: isolation valve, versatile connector, verify valve, isolation valve—and outline assist areas relative to the pump centerline. That pump connection turns into a product the store can fabricate identically, whether or not it is going right into a hospital chiller plant, workplace constructing mechanical room or college boiler room.

Standardized particulars cut back fabrication time and remove discipline guesswork about correct meeting. Practice each fab store employees and discipline crews on these customary connections to make sure constant high quality.

Finest Follow #3: Use Expertise to Bridge Mechanical Design and Fabrication

By leveraging BIM software program and mechanical producer libraries, development groups can streamline the design-to-shop transition. Sure manufacturer-specific BIM instruments comparable to VTFR combine element libraries to make sure designers work with elements retailers can truly procure and fabricate. For instance, with VTFR, when deciding on a grooved coupling from a digital library, the software program robotically accounts for precise dimensions, set up necessities and appropriate pipe schedules, eliminating situations the place designers specify incompatible connection varieties or fittings the store would not inventory.

Expertise additionally allows flexibility by way of automated conversion instruments that rapidly swap between piping connection varieties with out requiring designers to redraw connections. When a piece of welded pipe wants to vary to grooved connections due to area constraints, conversion instruments enable designers to pick out the affected segments and exchange all connections whereas sustaining routing and total dimensions.

Taking integration additional, contractors can join design software program immediately with mechanical fabrication gear to remove guide handoffs the place errors happen. When slicing and grooving machines learn immediately from the BIM mannequin, contractors remove guide transcription of measurements, eradicating a standard supply of fabrication errors—offered designers mannequin with the element fabrication requires. Digital libraries of normal mechanical elements additional guarantee consistency throughout piping initiatives. When designers can entry documented pump connections somewhat than recreating them, they use the requirements and everybody works from the identical data.

Finest Follow #4: Construction Manufacturing Cycles to Steadiness Effectivity and Flexibility

As soon as standardization and expertise integration are in place, contractors optimize their manufacturing scheduling by establishing structured manufacturing cycles that match their operational wants. The problem is balancing two competing calls for: lengthy manufacturing runs maximize store effectivity however lock contractors into single initiatives, whereas brief runs keep flexibility however cut back productiveness with fixed changeovers.

The answer lies in figuring out the appropriate cycle size on your operation. Calculate how a lot materials your discipline crews devour in a typical week, then construction manufacturing cycles that preserve them provided whereas sustaining the flexibility to change between initiatives. Many fabrication retailers discover cycles of three to 5 days strike this steadiness, however the optimum size depends upon store capability, crew measurement and the variety of energetic initiatives.

No matter particular timeframe, construction every cycle with distinct manufacturing phases. Group related operations collectively: slicing and grooving in a single part, meeting and helps in one other and remaining inspection and staging in a 3rd. This permits supervisors to catch points whereas they’re nonetheless in course of somewhat than discovering issues after a complete cycle is full.

This structured strategy additionally supplies pure choice factors. When initiatives encounter delays or design modifications, contractors can alter a single manufacturing cycle somewhat than unraveling weeks of dedicated work. Spool monitoring techniques such because the Victaulic SpoolTracker App might help retailers monitor element standing by way of every part and keep visibility throughout a number of initiatives, making it simpler to coordinate manufacturing with discipline demand.

Finest Follow #5: Design Mechanical Methods for Store Benefits

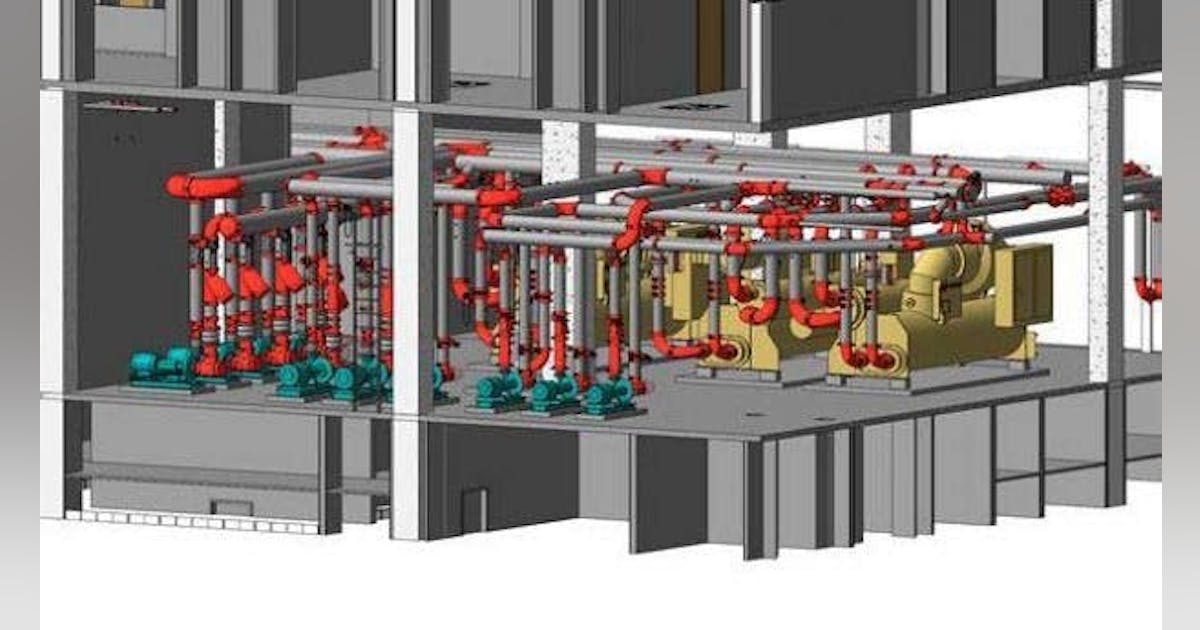

With standardization, expertise and scheduling optimized, the following step is to leverage managed store environments the place sustaining constant work high quality is less complicated than below discipline situations. Store flooring provide constant lighting, local weather management and bench-height work surfaces that enhance each pace and accuracy. A pipe meeting that takes 45 minutes to manufacture on web site with a number of interruptions can usually be accomplished in 20 minutes in a store. Pre-fabricated spools arrive on the job web site prepared for set up, with elements designed to suit into allotted area, decreasing conflicts and minimizing discipline changes.

Store fabrication helps protect the coordination established throughout the design part. Pre-fabricated assemblies cut back the variety of connections that should be made within the discipline. A mechanical room that will require 80 connections with stick-built pipe may want solely 30 with shop-fabricated spools. Fewer discipline connections imply sooner set up and extra constant joint high quality since shop-controlled situations allow extra exact meeting work.

Avoiding Widespread Pitfalls

Whereas these 5 practices present a roadmap, implementation requires cautious consideration to keep away from widespread missteps.

Do not bounce into fabrication with out correct coaching. Assess present BIM expertise and coordination expertise earlier than starting. If designers do not perceive learn how to coordinate mechanical, electrical and plumbing techniques in 3D, fabricating from these fashions will produce discipline conflicts.

Quite than making an attempt to standardize all the pieces directly, begin with the most typical connection varieties: pump hookups and valve assemblies. Get these proper and documented earlier than increasing to extra complicated situations.

Success additionally requires coaching design groups, fabricators and discipline crews collectively in order that they perceive one another’s challenges and capabilities. When a designer understands {that a} routing choice provides fabrication time, they route otherwise.

Set up metrics to trace progress. Measure materials waste percentages, set up hours per ton of kit and rework incidents to establish which requirements are performing and which want refinement.

Trending Merchandise

CRAFTSMAN Pliers, 8 & 10″, 2Piece Groove Joint Set (CMHT82547)

TT TRSMIMA Safety Harness Fall Protection Upgrade 4 Quick Buckles Construction Full Body Harness 6 Adjustment D-ring

BIC Wite-Out Brand EZ Correct Correction Tape, 19.8 Feet, 4-Count Pack of White Correction Tape, Fast, Clean and Easy to Use Tear-Resistant Tape Office or School Supplies

![KwikSafety – Charlotte, NC – TSUNAMI KIT [Premium BRAIDED ROPE] Vertical Lifeline, 1-D Ring Safety Harness, Lightweight Tool Lanyard, Roof Anchor, 20L Dry Bag ANSI OSHA Fall Protection System / 50 FT.](https://m.media-amazon.com/images/I/51inmgg4jlL._SS300_.jpg)