The breakthrough removes a key technical barrier that has held again low-carbon timber initiatives.

Till now, each CLT scheme required bespoke assessments as a result of an absence of standardised testing — a pricey and time-consuming course of that created uncertainty for design groups.

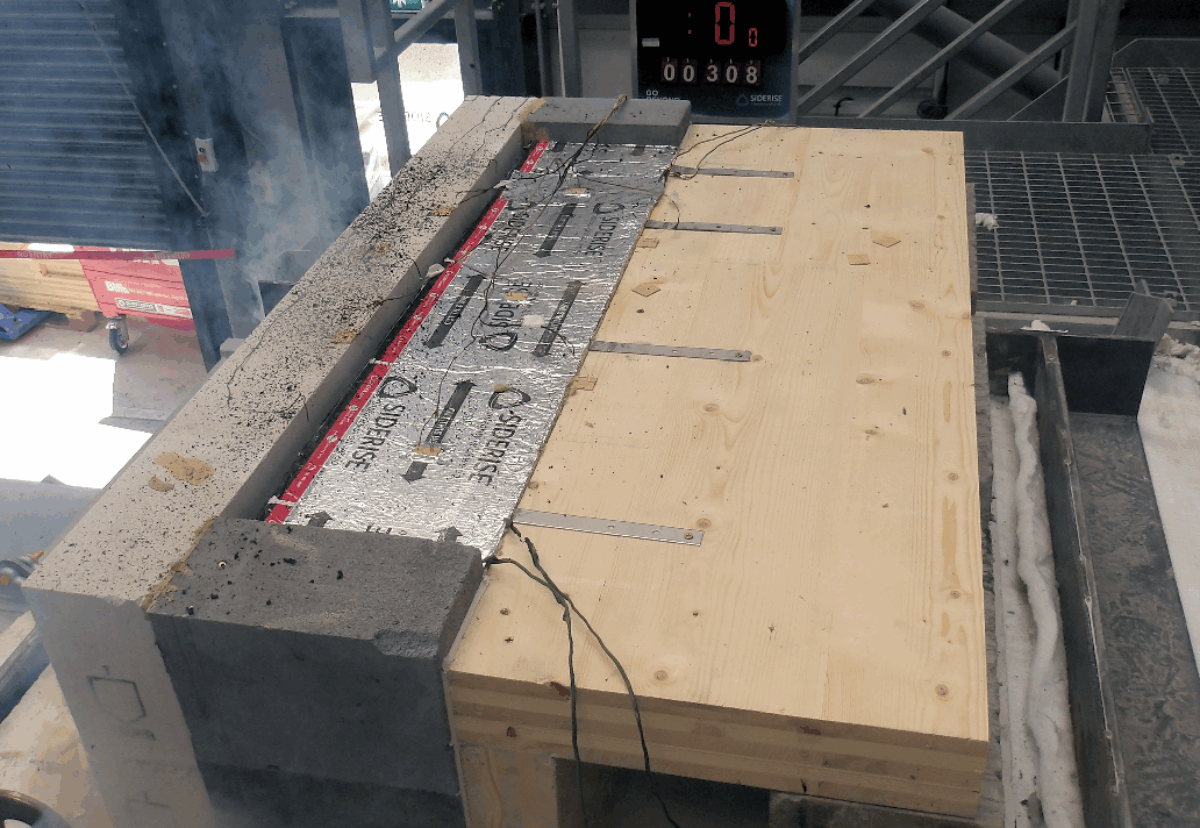

The builder joined forces with passive hearth safety specialist Siderise and Austrian CLT producer KLH to hold out the checks, which lastly present licensed particulars for cavity obstacles utilized in CLT wall and ground methods.

The checks, carried out at Siderise’s Innovation Centre in Maesteg in South Wales, lined three high-risk interface eventualities utilizing Siderise’s EW-CB and RH25 cavity obstacles.

All handed, together with the hardest “worst-case” checks utilizing 100mm five-layer CLT panels to European requirements EN1366-4 and prEN1364-6.

Willmott Dixon architectural technologist Jessica Winyard stated: “The work addresses a real technical hole that impacts each organisation working with CLT” and can assist speed up the shift to low-carbon development “whereas guaranteeing strong hearth security efficiency.”

The outcomes imply CLT initiatives can now use standardised cavity barrier particulars with out project-specific hearth testing — saving time, slicing value, and lowering danger.

![KwikSafety – Charlotte, NC – TSUNAMI KIT [Premium BRAIDED ROPE] Vertical Lifeline, 1-D Ring Safety Harness, Lightweight Tool Lanyard, Roof Anchor, 20L Dry Bag ANSI OSHA Fall Protection System / 50 FT.](https://m.media-amazon.com/images/I/51inmgg4jlL._SS300_.jpg)