Monitoring the progress of structural metal erection on any job is paramount. One incorrect or misplaced beam can probably put the entire venture in jeopardy.

But, the issues with how corporations observe metal are manifold — some corporations plunk information into an Excel spreadsheet, and there could be a discrepancy in information requirements amongst stakeholders on a venture.

Boston-based Suffolk Development has an answer that it developed in home. Stay Dimensions, created by Suffolk’s Director of Digital Engineering Denis Leff, makes use of BIM fashions to trace metal progress from design via fabrication and last development. It has already recognized frequent pitfalls within the erection course of, he mentioned, saving the agency time.

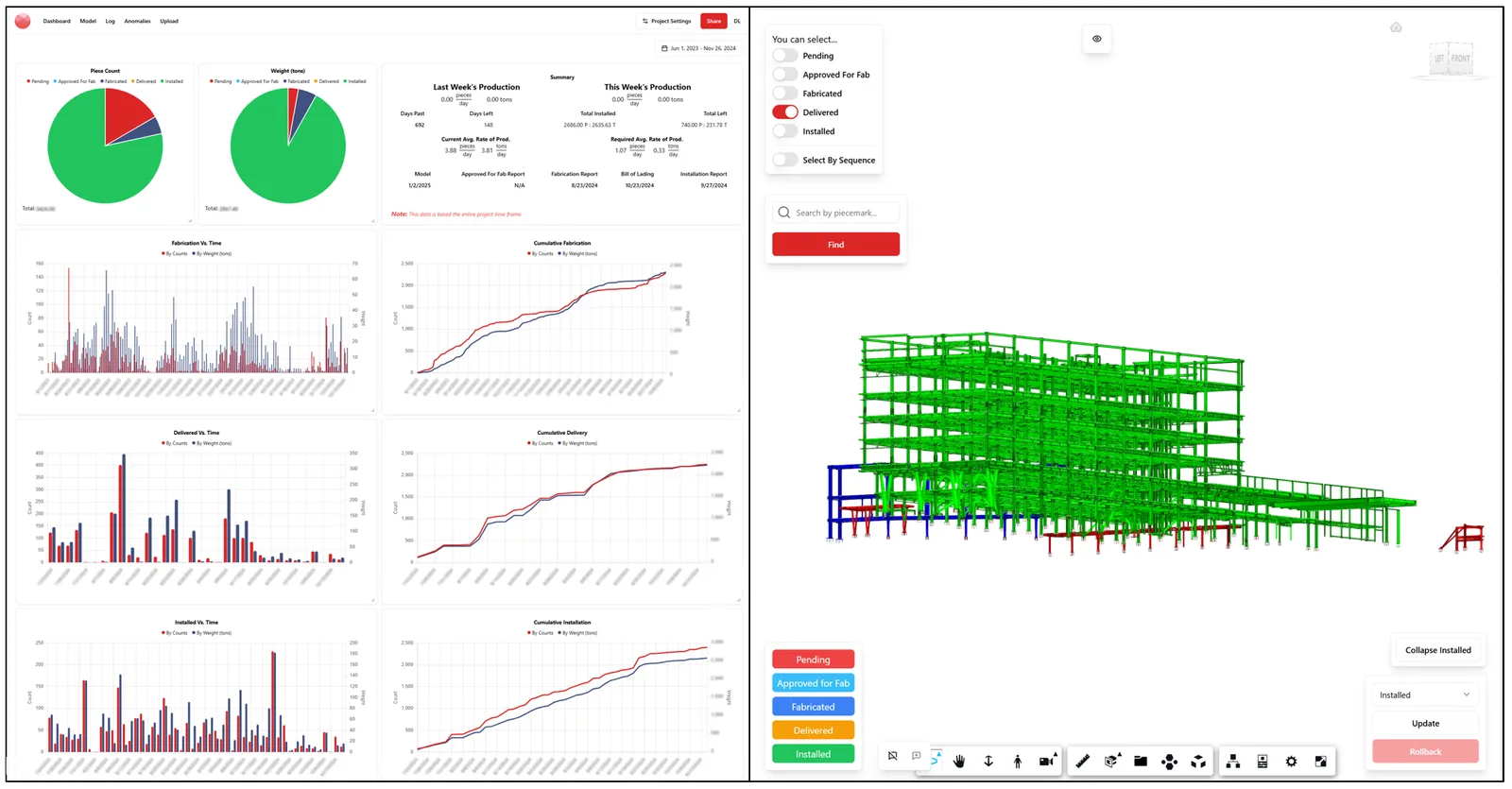

In a information launch, Suffolk mentioned Stay Dimensions makes use of synthetic intelligence to parse datasets and standardize info right into a unified database. That permits it to dynamically replace the BIM mannequin, which offers a real-time snapshot of a venture’s structural metal standing.

Secrets and techniques to success

Leff mentioned that his curiosity in tech started when he hung out working for Samsung in South Korea — he labored from 2010 to 2016 as a BIM growth supervisor on the firm’s development and buying and selling division headquarters in Seoul.

Since transferring on to Suffolk, Leff’s ardour has been bringing BIM to the plenty, even non-experts. Therefore, Stay Dimensions was born.

Denis Leff

Permission granted by Suffolk Development

“BIM fashions maintain all the data of what we’re about to construct,” Leff mentioned. “And I see them typically as underleveraged in our business, partially as a result of the know-how blocks lots of people. They do not know entry the information until you are a BIM knowledgeable.”

Presently, Suffolk is utilizing Stay Dimensions on its South Shore University Hospital Pavilion Core & Shell venture in Bay Shore, New York. The scope for the primary section of labor contains abatement and demolition, website utilities and the complete core and shell, based on the venture’s info web page. The $468 million project celebrated its metal topping out in October, and can be accomplished within the second quarter of 2026, based on the hospital community.

This system helped with two key points on the construct: monitoring completion and deliveries. It stored the crew from having to cope with piecemeal information entry into an Excel spreadsheet or utilizing pricey monitoring software program.

As an alternative, customers merely dragged and dropped a BIM mannequin into this system, marking it as prepared to trace. When metal was delivered, they then scanned the invoice of lading from the supply agency and uploaded it to Stay Dimensions.

“Figuring out the place the fabric is and what state it’s in to make sure continuity within the discipline is absolutely essential, since you do not simply cease metal if the metal isn’t prepared. You cease the whole venture,” Leff mentioned.

The modeling on Stay Dimensions for the South Shore College Hospital Pavilion venture in Bay Shore, New York.

Permission granted by Suffolk Development/Denis Leff

Whereas Leff mentioned it was too early to evaluate whether or not the device will help with mitigating rework, it’s been helpful in figuring out, and monitoring, the routine mishaps that may happen in the course of the erection course of, equivalent to bolt gap misalignments and broken beam alternative.

“A variety of these things is par for the course. It occurs on each venture,” Leff mentioned. “However we’re actually making an attempt to get an understanding — is it a venture in New York? Is it a specific contractor? Is it a specific fabricator? Is that this going to occur, roughly, with sure folks that we accomplice with?”

A give attention to innovation

Leff mentioned he constructed the software program in a six-month interval earlier than the corporate was going to place metal up on the South Shore venture. With the assistance of Matthew Chen, a digital engineering intern for the contractor, Leff additionally turned Stay Dimensions from an app right into a web-based platform.

Suffolk’s give attention to innovation made it straightforward to iterate the answer — the corporate has an in-house enterprise capital arm, Suffolk Ventures, which invests in development know-how throughout the constructing cycle.

“We’re very tech-forward as a corporation, so there’s lots of assist for reaching our targets, our passions, in the event that they match the invoice of transferring our firm ahead,” Leff mentioned.

If Leff had been to construct this program exterior of the corporate, he mentioned he’d be below extra time constraints.

“Right here, I will perceive the venture’s wants at a snug tempo, attempt issues out, reiterate, enhance,” Leff mentioned. “It isn’t like being an exterior individual making an attempt to create an answer for another person. You will have a bit of bit extra time to do issues thoughtfully, and that is why I am going one venture at a time.”

Trending Merchandise

CRAFTSMAN Pliers, 8 & 10″, 2Piece Groove Joint Set (CMHT82547)

TT TRSMIMA Safety Harness Fall Protection Upgrade 4 Quick Buckles Construction Full Body Harness 6 Adjustment D-ring

BIC Wite-Out Brand EZ Correct Correction Tape, 19.8 Feet, 4-Count Pack of White Correction Tape, Fast, Clean and Easy to Use Tear-Resistant Tape Office or School Supplies

![KwikSafety – Charlotte, NC – TSUNAMI KIT [Premium BRAIDED ROPE] Vertical Lifeline, 1-D Ring Safety Harness, Lightweight Tool Lanyard, Roof Anchor, 20L Dry Bag ANSI OSHA Fall Protection System / 50 FT.](https://m.media-amazon.com/images/I/51inmgg4jlL._SS300_.jpg)